NETZSCH Analyzing & Testing, a business unit of the NETZSCH Group, develops and manufactures high-precision instruments for thermal analysis, rheology, and fire testing. The company also provides world-class commercial testing services through its global laboratories. NETZSCH solutions support research and quality control across various industries, including polymers, chemicals, building materials, and environmental analysis.

FEATURED SOLUTIONS

Thermal Analysis / Calorimetry

Differential Scanning Calorimetry by NETZSCH

Differential Scanning Calorimeter (DSC/DTA)

Differential Scanning Calorimetry (DSC) investigates how the heat uptake or release of a sample material changes in comparison to a reference material when both are subjected to a controlled temperature change. This technique is very useful for determining phase transitions such as melting, crystallization, or chemical reactions.

Simultaneous Thermogravimetry and Differential Scanning Calorimetry by NETZSCH

Simultaneous Thermal Analyzer (STA/TGA-DSC)

Simultaneous Thermal Analysis (STA) generally refers to the simultaneous application of Thermogravimetry (TGA for measuring mass changes) and Differential Scanning Calorimetry (DSC for measuring energy conversion) to one and the same sample with a single instrument.

The modular design of NETZSCH simultaneous thermal analyzers allows for easy exchange of furnaces and sensors to accommodate multiple applications over a wide temperature range from -150°C to 2400°C. The top-loading design provides ideal performance and ease of use, making it the obvious choice for a flexible analytical system and evolved gas analysis such as MS, FT-IR, or GC-MS systems. A wide range of accessories, including humidity and water vapor generators, expand the application possibilities.

Thermogravimetric Analyzer Technology by NETZSCH

Thermogravimetric Analyzer (TGA)

Thermogravimetric analysis or thermogravimetry (TGA/TG) is a method of thermal analysis in which the mass of a sample is measured over time as the temperature changes. This measurement provides information about the thermal stability of samples, their composition (via the decomposition of different components), solid-gas reactions such as absorption, desorption, oxidation or reduction and, using the c-DTA® functionality, even phase transitions.

For measuring both the thermal and the mechanical properties, a thermomechanical analyzer (TMA) is used.

Thermomechanical Analyzer (TMA)

Many materials undergo changes to their thermomechanical properties during heating or cooling. For example, phase changes, sintering steps or softening can occur in addition to thermal expansion. TMA analyses can hereby provide valuable insight into the composition, structure, production conditions or application possibilities for various materials.

For measuring the viscoelastic properties of materials

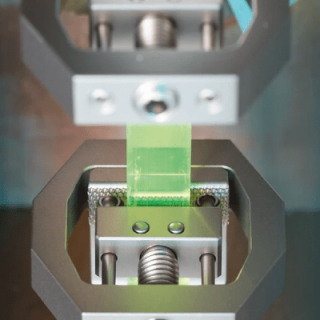

Dynamic Mechanical Analyzer (DMA)

Dynamic Mechanical Analysis (DMA) is a technique used to evaluate the viscoelastic properties of materials, particularly polymers, by applying an oscillating load. Stress and strain at the sample are measured to determine properties such as modulus and damping behavior under varying temperature and frequency conditions.

The main advantage of Dynamic Mechanical Analysis (DMA) is its ability to provide detailed insight into the viscoelastic properties of materials, enabling accurate characterization of their mechanical behavior, which is critical for applications in materials development and quality control.

Multiple Module Calorimeter (MMC)

A calorimeter device consisting of a base unit and exchangeable modules. One module is prepared for accelerating rate calorimetry (ARC®), a second one is used for scanning tests (Scanning Module) and a third one is related to battery testing for coin cells (Coin Cell Module).

The NETZSCH development team has created a totally new calorimeter system which can be used in commercial R&D, universities and research centers and QC/QA of various industries.

Dilatometry (DIL) is the method of choice for highly precise measurements of dimensional changes of solids, melts, powders and pastes during a programmed temperature change with negligible sample load.

Dilatometer (DIL)

DIL allows for the study of length change phenomena of ceramics, glass, metals, polymers, composite materials, and refractory materials, thus providing insight into their thermal behavior and process parameters or sintering kinetics.

DIL systems are based on relevant instrument and application standards, e.g., ASTM E228, ASTM D696, DIN 51045 and DIN EN 821.

Accelerating Rate Calorimeter (ARC®) Technology by NETZSCH

Accelerating Rate Calorimeter (ARC®)

Accelerating Rate Calorimetry (ARC®) is the gold standard for process safety testing, thermal runaway analysis, and reaction hazard evaluation. The method, describing isothermal and adiabatic test procedures, is used to detect thermally induced exothermic decomposition reactions. The standard procedure is Heat-Wait-Search (HWS).

Dielectric Analyzer (DEA)

For investigation of the curing behavior of thermosetting resin systems, composite materials, adhesives and paints, Dielectric Analysis (DEA) in accordance with ASTM E2038 or E2039 has stood the test of time.

Dielectric Analysis (DEA), also known as Dielectric Thermal Analysis (DETA), is a technique for monitoring changes in viscosity and the cure state of thermosetting resins, adhesives, paints, composites and other kinds of polymers or organic substances by measuring variations in their dielectric properties.

Refractoriness under load (RUL) / Creep in compression (CIC)

Refractory Tester

Special strength-testing methods have been established for refractory ceramics, which are of a mostly heterogeneous composition. The Refractoriness under Load (RUL) and Creep in Compression (CIC) identify the deformation resistance of a test piece under a defined load and temperature/time factors. These all conform to the pertinent instrument and applications standards, e.g. ISO 1893, ISO 3187, ISO 5013, DIN EN 993-7/8/9, DIN 51048, DIN 51053, DIN 51063, DIN 51046.

Thermophysical Properties Analysis

For measuring the Thermal Diffusivity and Thermal Conductivity

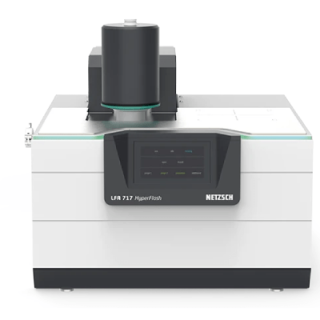

Light/Laser Flash Analyzer (LFA)

Understanding thermal conductivity is critical to material selection for various applications. Insulation materials require low thermal conductivity, while heat sinks require high conductivity for effective heat dissipation. In industrial processes such as casting and welding, thermal conductivity affects the movement of heat, affecting efficiency and quality. In addition, thermal diffusivity is critical in rapid heating and cooling scenarios where heat transfer varies over time.

One accurate, reliable and elegant solution to measure thermal conductivity and thermal diffusivity is offered by the Flash/Laser Method. NETZSCH offers three models that cover the entire spectrum of materials and temperatures.

For determining the thermal diffusivity and thermal conductivity of thin films with thicknesses in the nanometer range

Time Domain Thermoreflectance Analyzer (TDTR)

The LFA method can typically be used on samples with a thickness of between 0.1 mm and 6 mm. However, with ever-advancing designs in electronic instruments and the associated demand for efficient thermal management, it is more important than ever to achieve precise measurements of thermal diffusivity, thermal conductivity and transition contact resistance into the nanometer range. In this application area, materials range in thickness from 10 nm to 2 µm. They may take the form of phase change storage (PCM), thermoelectric thin films, light-emitting diodes (LED), dielectric interface layers or even transparent conductive films (TCF).

Heat Flow Meter (HFM) and Guarded Heat Flow Meter (GHFM) Technology by NETZSCH

Heat Flow Meter (HFM) / Guarded Heat Flow Meter (GHFM)

The Heat Flow Meter (HFM) method determines the thermal conductivity of materials by applying a steady-state heat transfer method. It is particularly effective for testing low-conductivity materials such as insulations. The system measures the heat flux across a specimen placed between two plates with a known temperature gradient.

The Guarded Heat Flow Meter (GHFM) method involves placing a specimen between two plates controlled at different temperatures. Multiple RTD sensors measure the temperatures on each side, while heat flux sensors measure the heat flow caused by the temperature gradient. To prevent lateral heat loss, an active guard is incorporated.

Guarded Hot Plate (GHP) and Guarded Hot Pipe (TLR) Technology by NETZSCH

Guarded Hot Plate/Pipe (GHP/TLR)

With these technologies, NETZSCH offers state-of-the-art instruments for measuring the thermal conductivity of building, construction and insulating materials. GHP (guarded hot plate) devices are in accordance with ISO 8302; TLR (guarded hot pipe) devices are in accordance with DIN EN ISO 8497.

These NETZSCH instruments provide highly accurate, absolute measurements of thermal conductivity and thermal resistance, as well as a calculated U-value for materials with low conductivity.

Determining the stationary heat transfer properties of complex components and finished products used in construction such as doors, windows and bricks

Hotbox Test Chambers (TDW)

In a world increasingly focusing on sustainability, energy efficiency, and safety, accurate knowledge of the heat transfer properties of building materials is crucial. Whether it’s about the insulation of buildings, the efficiency of windows and doors, or the overall energy balance of facades, precise determination of these properties is essential. This is where the innovative Hotbox test chambers come into play – the ultimate solution for measuring and analyzing the heat transfer properties of wall elements, walls, windows and doors.

Evolved Gas Analysis

How to Detect and Identify Evolved Gases - Almost Half a Century of Development Experience in Coupling Technologies

Evolved Gas Analyzer (EGA, coupled to Thermal Analyzer)

By coupling a Thermobalance (TG, TGA) or Simultaneous Thermal Analyzer (STA, TGA-DSC) with a Quadrupole Mass Spectrometer (QMS), it is possible to detect and identify evolved gases in exact time correlation with TGA or STA signals.

The Combination with an FT-IR (Fourier Transform Infrared Spectrometer) has become an absolute must, especially in the polymer-producing, chemical and pharmaceutical industries.

Rheology

Rotational Rheometry

The rheological analysis of samples is a fundamental part of developing many types of products. Unlike a viscometer, a rheometer can actually measure sample properties at extremely low shear rates, as in sedimentation, or the high shear rates seen in pumping, mixing and application and making measurements in the correct shear range, we can adequately simulate a flow process and so differentiate good products from poor ones. The rheometer can also determine the effect of adding different quantities of an additive, or process changes and so be used to optimize the formulation and production of a product.

Capillary Rheometry

With the Rosand capillary rheometer, a sample is loaded into a cylindrical barrel that is pre-set at the required test temperature. A servo-drive controlled piston is then used to extrude the sample material through a cylindrical or rectangular slot die in place at the end of the barrel at a very controlled series of speeds (volumetric flow rate). The pressure drop across the die is continuously monitored and measured with a pressure transducer placed just above the die. A cut away is shown in Figure 1. The Rosand capillary rheometers can accommodate a wide range of pressure transducers and dies, making them versatile for measuring a broad spectrum of sample types. Typical sample viscosities can range from ink jet ink to highly-filled, high modulus rubber samples. The standard instrument’s temperature range is generally from ambient to 400°C (with cryogenic cooling and 500°C max temperature as option s).

Fire Testing

Fire Testing Systems

For preventive fire protection, the appropriate choice of materials and components is essential in order to prevent fires altogether or prevent them from spreading. The basis for this decision are fire tests according to German, European and international standards used to classify the flammability and the burn rate of materials for the construction, textile, automobile and electrical industry.

For the construction industry, especially the reaction to fire of building materials with the resulting parameters flammability, flame spread, flaming droplets, combustibility, heat release, calorific value, smoke production and toxicity as well as the fire resistance of building components are of relevance.

Software

Kinetics

Software for kinetic analysis of thermoanalytical data for chemical processes.

Prediction of process behaviour and temperature optimization based on kinetics analysis.

Kinetics Neo software fully supports mandatory rules for kinetic analysis: “ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics”.

Termica

Software for Thermal Simulation of Chemical Reactions on an Industrial Scale

ASK US ANYTHING

ADDRESS

Gulf Scientific Corporation

PO Box 17010

Street N500 Jebel Ali Freezone (JAFZA 4)

Dubai, United Arab Emirates

OPENING HOURS

08:00 - 17:00

CONTACT

Tel: +971 4 881 5270

Fax: +971 4 881 6778